Since the early 2000s, the global all-ceramic restoration market, including that for zirconia, has been growing rapidly. Increasing market demand resulted in various dental manufacturers marketing different dental zirconia types usable in many dental prosthetic applications. These are the top 5 things to know when using dental zirconia.

1. THE TYPE/BRAND OF DENTAL ZIRCONIA

During the industrial process of making dental zirconia (zirconium dioxide), yttria (Y2O3) is added to make refined zirconia stable at room temperature. Yttria also contributes to increasing the translucency of zirconia yet conversely reduces its strength. The most common method of classifying zirconia is by yttria concentration (ie, 3Y, 4Y, or 5Y). Many dental manufacturers use/buy zirconia from one large industrial ceramic manufacturer. This classification helps describe the properties of zirconia when the primary powder source is the same. The strongest and least translucent is 3Y, whereas 5Y has the highest translucency and lowest strength.

Only a few manufacturers, like Kuraray Noritake Dental, Inc, use their own proprietary original zirconia powder formulations (Figure 1). The company can thereby more accurately control the chemical and physical makeup not only with yttria concentration but also with parameters such as grain, particle size, and sintering temperature.

Figure 1. Kuraray Noritake Dental, Inc, original KATANA Zirconia powder.

2. THE STRENGTH OF THE ZIRCONIA

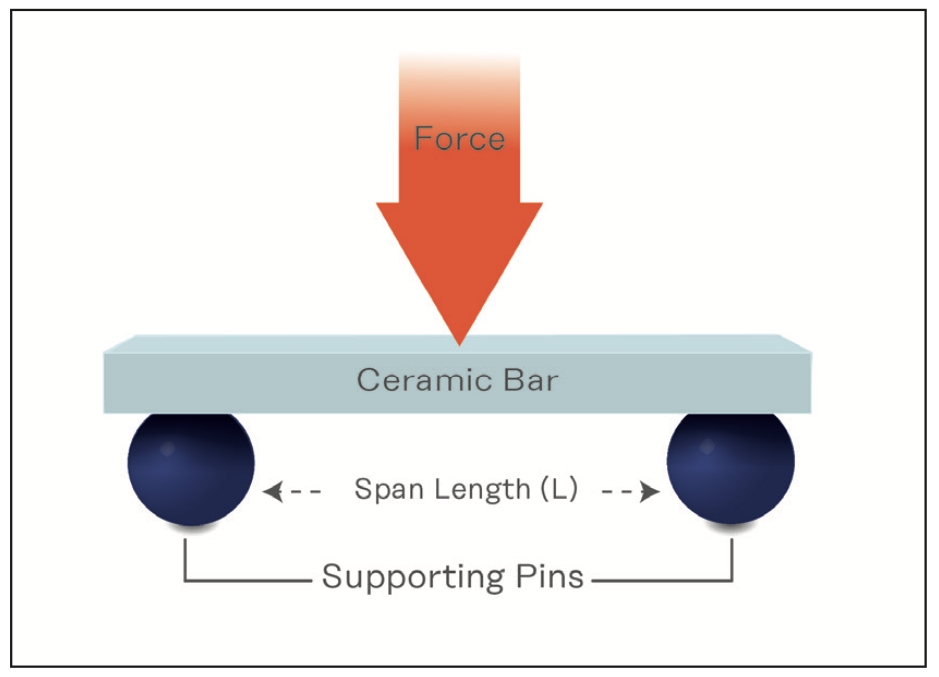

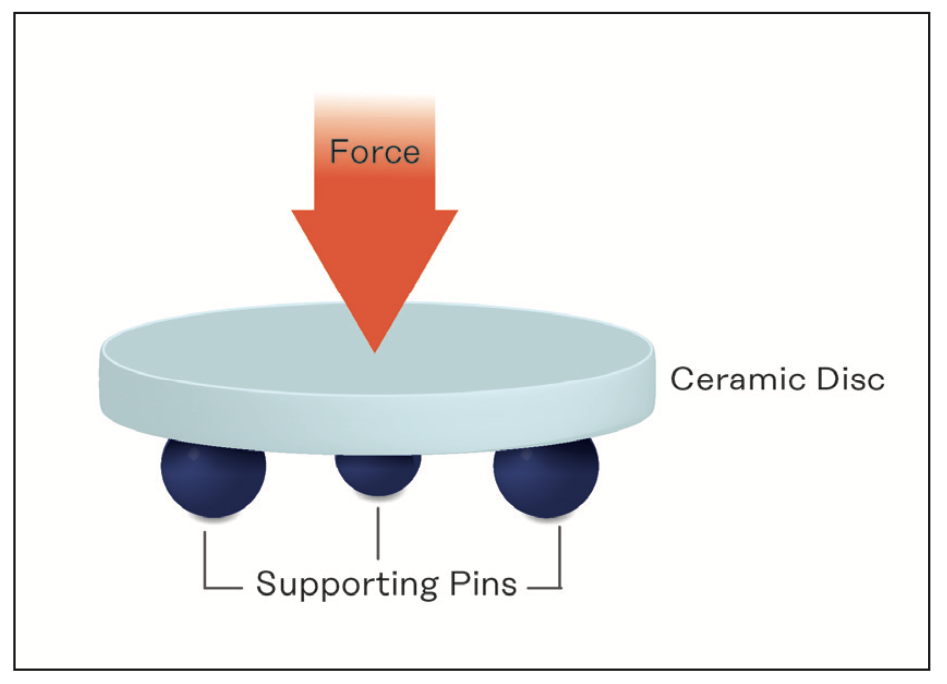

The most common method of measuring ceramic strength is by evaluating its flexural strength. The flexural strength test applies a force on the top of a ceramic specimen, which causes the specimen to bend and fracture. Two methodologies are commonly used today. In the 3-point bend method (Figure 2), a rectangular specimen is used, whereas in the biaxial flexural strength method (Figure 3), a circular specimen is incorporated. Both tests are acceptable; however, ceramics tend to produce higher values when tested with the biaxial method compared to the 3-point bend method. Furthermore, even in a 3-point bending test, if the span length of the specimen is decreased, it can produce higher values of flexural strength of the same ceramic. It is critical to understand testing parameters when selecting or comparing different ceramic brands.

Figure 2. Three-point bending flexural strength test.

Figure 3. Biaxial bending flexural strength test.

3. IF THE ZIRCONIA IS MULTICHROMATIC OR MULTI-TRANSLUCENT

Kuraray Noritake was the first dental manufacturer to introduce multilayered zirconia as a commercial product in 2013. Different concentrations of pigment-containing zirconia powder are utilized to make the zirconia discs and blocks multichromatic.

Multichromatic: The yttria concentration remains similar in all layers; therefore, the strength of the zirconia does not deviate from layer to layer. The pigments (chroma) are adjusted in a way that produces different chroma among the layers while the translucency stays the same.

Multi-translucent: KATANA Zirconia YML (Kuraray Noritake) (Figure 4) is the latest KATANA multilayered disc, with a well-balanced combination of color translucency and flexural strength gradation. It is also manufactured using multilayer technology, with different yttria content (and strength) in each layer.

Figure 4. KATANA Zirconia YML (Kuraray Noritake).

4. HOW TO CLEAN ZIRCONIA

During trial-fitting, the zirconia restoration might become contaminated with salivary proteins, thereby reducing bond strength. KATANA Cleaner (Kuraray Noritake) can be used to remove contamination by rubbing it on the intaglio surface and subsequently rinsing it with water.

5. ZIRCONIA BONDING TECHNIQUES

There are several clinical situations in which zirconia restorations benefit from resin bonding: restorations that are not as strong or thin, lack retention, or rely on resin bonding (eg, resin-bonded fixed partial prostheses, onlays, or laminate veneers). Prof. Markus Blatz and his group introduced a 3-step approach, known as the “APC Zirconia Bonding Technique.”

Step A in “APC” stands for air-particle abrasion; followed by step P, primer application; and finally, step C: the use of composite resin. MDP has shown a very stable chemical bond to zirconia. Kuraray Noritake invented and introduced the original MDP monomer in 1981. All Kuraray Noritake PANAVIA cement brands contain this original MDP monomer.

For more information, call Kuraray America at (800) 879-1676 or visit kuraraydental.com.